|

|

Build Your Online Product Catalogs?

| Product Name: |

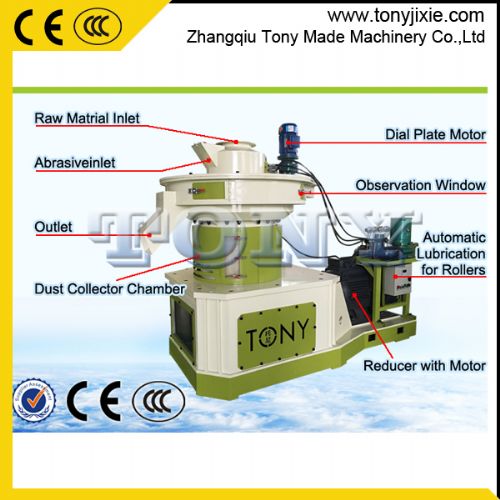

Biomass Ring Die Alfafa Pellet Machine

|

| Supply Ability: |

1000 Sets |

| Related proudcts |

pellet mill, pellet machine, |

| Specifications |

2000*1100*1800mm,1-8t,90-550kw |

| Price Term: |

FOB/CIF |

| Port of loading: |

Qingdao |

| Minimum Order |

1 set |

| Unit Price: |

15000-50000 |

|

Warm Tips of the wood pellet mill:

Motors: producing according to customers, include voltage, rated power and brand;

If no requirement, generally 380V, 50HZ, 3 phase.

Price: the price displayed on the web is not the fixed price, but a scope of all this series products price, just for your reference only! For ***alied information, pls feel freely to contact me.

Requirements for raw materials of wood pellet mill:

Raw material of the wood pellet mill: wood, waste wood and straws, etc. such as woodchips(palm, pine white pine, mahogany, pinus sylvestris, rubber tree), bamboo shavings, rice hust, seeds shells, peanut shells, halm, pennisetum, wheat straw, corn stalk, cotton stalks, alfalfa grass, bagrass, palm fiber, waste paper, non-physical material

Size:1-5mm (All the raw materials must be crushed into sawdust before going

to wood pellet mill.If not, you may need a wood chipper, wood crusher.)

Moisture: Generally, 10-15% is best for producing good quality wood pellet.

***re parts of pellet machine:

Ring die of wood pellet machine---1500-2000 hours service time

Rollers of wood pellet machine----3000-4000 hours service time

High Efficient Wood Pellet Mill have the following characteristic:

1. Vertical feeding, directly in place.

2. Die is static, rollers rotary; materials are evenly distributed around, because of centrifugal force.

3. Double layer die.:Two layers both can be used independently so the machine reduces the cost; What's more, two layers of the die also can be used at the same time, in this way, the efficiency has been improved greatly, high capacity and save energy.

4.Ring die and vertical structure are good for cooling the pelletizing room.

5.Independent and frequency conversion discharge device can ensure the rate of pellet formation. |

| Company: |

Zhangqiu Tony Made Machinery Co.LTD

|

| Contact: |

Ms. Vivian Wang |

| Address: |

liugang road |

| Postcode: |

|

| Tel: |

0086-531-83698878 |

| Fax: |

0086-531-83698868 |

| E-mail: |

|

|

|

|